Stay Ahead of Wear and Tear: Important Maintenance Tips for Undercarriage Parts

Wiki Article

Discover Undercarriage Parts for Heavy Machinery

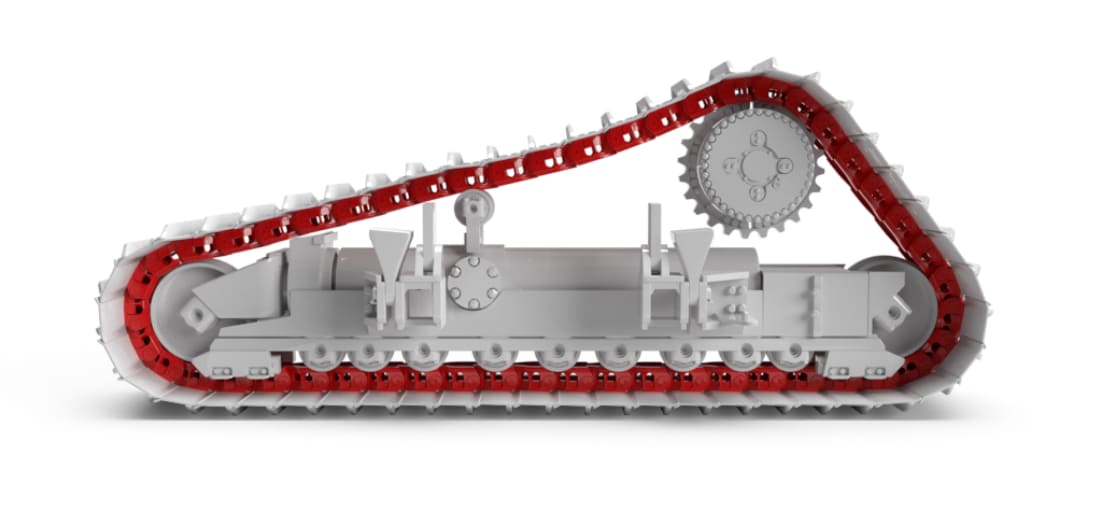

Understanding the ins and outs of undercarriage parts is vital for the optimal performance and long life of heavy machinery. From track shoes to idlers, rollers, and gears, each part plays a critical role in the capability of the equipment.Importance of Undercarriage Parts

The undercarriage parts of hefty equipment play an important function in making certain the general efficiency and long life of the tools. These elements, consisting of tracks, rollers, chains, sprockets, and idlers, develop the structure upon which the maker operates. A well-maintained undercarriage not just gives stability and assistance to the hefty equipment but likewise contributes considerably to its operational effectiveness and efficiency.

Among the vital advantages of buying high-grade undercarriage parts is the reduction of downtime and maintenance prices. By utilizing resilient components that can endure the rigors of durable applications, drivers can lessen the requirement for frequent repairs and replacements, therefore taking full advantage of the maker's uptime and total lifespan.

In addition, effectively operating undercarriage parts guarantee optimal weight grip, ability to move, and distribution, allowing the hefty machinery to operate smoothly even in difficult surfaces. This dependability is crucial for industries such as construction, mining, and farming, where tools performance directly affects task timelines and profitability. To conclude, the importance of undercarriage components can not be overemphasized in maintaining the efficiency and longevity of heavy machinery.

Kinds Of Track Shoes

When thinking about the numerous kinds of track shoes for hefty equipment, it is necessary to evaluate their layout and functionality in connection with details functional requirements. Track shoes are essential elements of the undercarriage system, providing traction, weight, and security circulation for hefty equipment such as excavators, excavators, and spider cranes.The most typical types of track footwear include:

** Grouser Shoes **: Including elevated steel bars (grousers) along the footwear's surface area, these track footwear provide boosted traction in tough terrains like mud, snow, and loosened crushed rock. undercarriage parts.

** Double Grouser Shoes **: Similar to grouser footwear yet with an additional collection of grousers, these track footwear provide also better grip and security, making them excellent for incredibly rough terrains.

** Triple Grouser Shoes **: With three sets of grousers, these track shoes supply maximum traction and stability, making them ideal for the most demanding conditions.

Choosing the appropriate type of track footwear is crucial for maximizing the efficiency and durability of hefty machinery while ensuring safety and performance throughout procedures.

Function of Rollers and Idlers

Rollers and idlers play indispensable duties in supporting and assisting the track footwear of hefty machinery during procedure. By avoiding excessive slack or tightness in the tracks, idlers add to the overall stability and efficiency of the machinery.In addition, idlers and rollers interact to maintain the track footwear abreast, preventing them from slipping or derailing off during procedure. Correctly functioning rollers and idlers are important for making sure the long life of the undercarriage system and making the most of the equipment's efficiency. Routine maintenance and inspection of these components are necessary to identify any type of signs of wear or damage beforehand, avoiding expensive repair about his work and downtime in the lengthy run.

Role of Sprockets in Equipment

Upkeep Tips for Undercarriage Elements

Efficient upkeep of undercarriage elements is important for guaranteeing the durability and ideal efficiency of heavy machinery. Normal evaluation of undercarriage parts Check Out Your URL such as track chains, rollers, idlers, sprockets, and track shoes is essential to protect against unanticipated breakdowns and expensive fixings. It is likewise essential to make sure appropriate track stress to stop early wear on elements.Verdict

Finally, the undercarriage parts of heavy machinery play a critical function in making certain the smooth functioning and longevity of the devices. Comprehending the relevance of track shoes, idlers, rollers, and gears, as well as applying appropriate upkeep techniques, can greatly influence the general efficiency and effectiveness of the equipment (undercarriage parts). Routine inspection and timely replacement of worn-out parts are essential in taking full advantage of the lifespan and productivity of heavy equipmentRollers and idlers play integral duties in sustaining and directing the track footwear of hefty equipment throughout procedure.In hefty equipment, gears offer an essential feature in transferring power from the engine to the tracks, making it possible for the devices to move successfully and successfully. These components are attached to the axles or final drives of the equipment and work in conjunction with the tracks to move the equipment ahead or backward. Routine examination of undercarriage components such as track chains, rollers, idlers, websites sprockets, and track shoes is essential to prevent pricey repairs and unforeseen break downs. Understanding the relevance of track shoes, idlers, gears, and rollers, as well as carrying out appropriate upkeep methods, can greatly affect the total efficiency and efficiency of the equipment.

Report this wiki page